In our environmental lab, we perform Ingress Protection (IP) testing to evaluate the resistance of products to water penetration under various conditions. The IP ratings are defined under the IEC 60529 standard and ensure that products meet specific protection levels against water exposure.

IP-X12 System

- The IP-X1/2 system, measuring 1×1 meter and 1.8 meters in height, enables water resistance tests as per IPX-1/2 standards, ensuring accurate water distribution at defined angles and distances.

- IP-X1/2 provides a 1×1 meter test area, suitable for testing resistance to vertical dripping water (IPX-1) and splashes at angles up to 15 degrees (IPX-2) as per the standard requirements.

- With a height of 1.8 meters, the system ensures uniform water distribution to test sealing under defined conditions, accommodating wider and longer products.

- The IP-X1/2 system enables precise water resistance testing at various angles and controlled quantities, compliant with IPX-1/2 standards, and offers adequate space for larger devices.

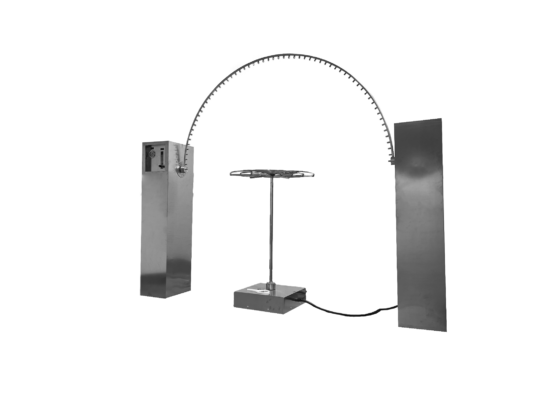

IP-X34 System

- The IP-X34 system is designed to meet IEC standards for IPX-3 and IPX-4 tests, enabling spray testing at varying pressures and angles to verify water resistance under civilian conditions.

- The system complies with IEC 60529 civilian standards, conducting controlled water spray tests to ensure product resistance in everyday environmental conditions.

- IP-X34 features precise pressure and angle control mechanisms, delivering accurate water resistance testing for a variety of civilian products.

- The system ensures testing aligns with actual usage conditions, such as exposure to water in open environments and urban infrastructure.

IP-X56 System

- The IP-X56 system is designed for water resistance testing under extreme conditions as per IEC standards, providing high-pressure water distribution to validate product durability in challenging scenarios.

- The system performs tests according to IPX-5 and IPX-6 standards, using high pressures to ensure maximum protection against water ingress in civilian-use products.

- IP-X56 is suited for testing products requiring resistance to strong water flows, using powerful jets to evaluate enclosure strength and sealing capabilities.

- The system is built to meet civilian standards, offering high-intensity testing simulating harsh environmental conditions, such as heavy rain or strong water sprays.

IP-X78 System

- The IP-X78 system is designed for water immersion testing according to IPX-7 and IPX-8 standards, with capabilities for immersion at depths up to 50 meters, based on manufacturer requirements.

- The system performs prolonged immersion tests at varying depths, ensuring product durability under challenging submersion conditions as per IPX-8 standards, including high-pressure scenarios in deep water environments.

- IP-X78 provides precise monitoring and control over testing processes, ideal for evaluating products meant to operate at significant depths while maintaining complete sealing.

- This system is specially engineered for deep immersion tests, enabling assessment of product sealing capabilities across a broad range of depths, from IPX-7 standards to tens of meters under IPX-8 criteria.

1. Purpose of IP Testing

IP testing helps determine:

- Water Resistance: Assess a product’s ability to withstand water exposure in controlled conditions.

- Performance Reliability: Ensure proper functionality of the product after exposure to water.

- Durability Validation: Verify if enclosures and materials meet industry standards for water protection.

2. IP Ratings We Test in Our Lab

IPX1 – Vertical Water Drip

- Condition: Water drips vertically onto the test sample.

- Duration: 10 minutes.

- Application: Products exposed to minimal water drips, such as indoor electronics.

IPX2 – Dripping Water at 15° Tilt

- Condition: Water drips at a 15° angle in four directions.

- Duration: 2.5 minutes per direction (total 10 minutes).

- Application: Devices where slight tilts or angles are possible, such as appliances or sensors.

IPX3 – Water Spray at 60°

- Condition: Water sprayed at an angle up to 60° from vertical using oscillating nozzles.

- Duration: 10 minutes.

- Application: Outdoor equipment or enclosures with exposure to rain or spraying water.

IPX4 – Water Splashing from All Directions

- Condition: Water splashes from all directions using oscillating nozzles or handheld spray.

- Duration: 10 minutes.

- Application: Products exposed to water splashes, such as lighting fixtures or outdoor appliances.

IPX7 – Temporary Immersion in Water

- Condition: The sample is submerged in water up to 1 meter deep.

- Duration: 30 minutes.

- Application: Devices requiring protection against brief immersion, like portable electronics or wearables.

IPX8 – Continuous Immersion in Water

- Condition: The sample is submerged beyond 1 meter of water depth under specified pressure and duration.

- Duration: Defined by agreement (customized for test requirements).

- Application: Products designed for continuous underwater use, such as waterproof phones, sensors, or marine equipment.

3. Testing Process in Our Lab

- Sample Preparation:

- Ensuring the sample is clean and sealed (if required).

- Test Execution:

- IPX1 to IPX4:

- Use of calibrated equipment (drip boxes, oscillating nozzles, or handheld sprays).

- IPX7 and IPX8:

- Controlled water immersion tanks with pressure and depth monitoring.

- IPX1 to IPX4:

- Monitoring:

- Real-time observation of water exposure and ingress into the product.

- Post-test inspection to assess for water penetration or damage.

- Post-Test Analysis:

- Verify functionality and performance of the product after exposure.

- Document any signs of water ingress, failures, or physical damage.

4. Applications of IP Testing

- Consumer Electronics: Phones, tablets, and wearables requiring water resistance.

- Automotive Components: Parts exposed to rain, splashes, or immersion.

- Outdoor Equipment: Lighting fixtures, sensors, and enclosures exposed to the environment.

- Marine Products: Devices or materials used in underwater conditions.

- Appliances: Washing machines, refrigerators, and other household devices exposed to water.

5. Benefits of IP Testing

- Ensure compliance with IEC 60529 and other industry standards.

- Increase product reliability and durability in real-world conditions.

- Prevent failures caused by water ingress, improving customer satisfaction.

- Validate waterproof designs for marketing claims.

Conclusion

With our comprehensive IP testing capabilities for IPX1, IPX2, IPX3, IPX4, IPX7, and IPX8, we ensure that products meet strict water protection standards. Whether for consumer electronics, industrial equipment, or outdoor applications, our lab provides accurate and reliable testing results.

For more details or to schedule an IP test, feel free to contact us!